Denny K. S. Ng

As reported by Germany’s Union for the Promotion of Oil and Protein Plants (UFOP), palm oil products remain the most important vegetable oil on the world market. It is expected to reach total 222.8M tonnes in 2023/24 (United States Department of Agriculture (USDA), 2023).

To meet the global emission target, all sectors are transition towards low carbon economy. As the largest global vegetable oil industry, palm oil is also expected to decarbonise the value chain to support the global transition plan. In the last decade, various initiatives and certification systems have been developed to promote sustainable palm oil production, such as, Roundtable on Sustainable Palm Oil (RSPO), Malaysia Sustainable Palm Oil (MSPO), Indonesia Sustainable Palm Oil (ISPO), etc. Such certifications are focusing on auditing the current practices and promote sustainable production of palm oil products. As part of the certification process, carbon emission from various activities in transportation, processing facilities and plantation are measured based on theoretical calculation.

Palm Oil Value Chain & Emission

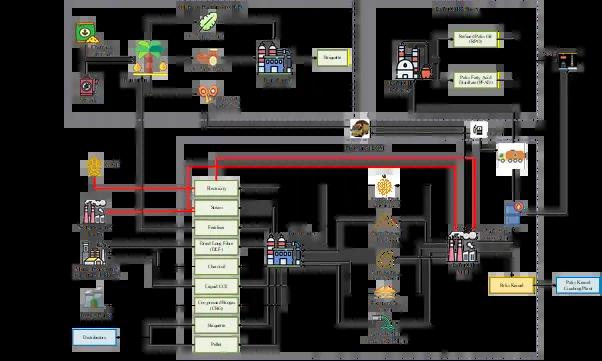

A typical palm oil value chain includes oil palm plantations (OPP), palm oil mills (POM), and palm oil refineries (POR) as well as transportation. As shown in Figure 1, the value chain is closely integrated to maximise the recovery of the energy and materials. Fresh fruit bunch (FBB) is harvested from oil palm plantation (OPP) and transported to palm oil mill for extraction of crude palm oil (CPO). During the extraction of CPO, various palm-based biomasses (empty fruit bunches, EFBs; palm pressed fibre, PPF; palm kernel shell, PKS; decanter cake, DC and palm oil mill effluent, POME) are generated. Such biomasses are then further converted to various products (e.g., electricity, steam, fertiliser, dried long fibre, etc.) via different technologies in biorefinery. The produced fertiliser can be returned to the OPP to reduce the consumption of chemical fertilisers. Meanwhile, the produced CPO in palm oil mill is transported to refinery to produce refined palm oil products which supply to local and international markets.

Noted that various external materials (pesticide, fertiliser, etc.) energy (heat and power) and fuels (diesel for machinery and transportation) are consumed to support the operation of the entire value chain. The effluent generated in palm oil mill (POME) releases significant amount of greenhouse gases to the atmosphere, if such gases are not captured and utilised. In addition, deforestation and land-use change in OPP has also contributed to the carbon emission of the palm oil value chain. Many life cycle assessments have been conducted for palm oil plantation, processing facilities and transportation to understand the potential of carbon emission from the value chain based on different industry practices, land use-changes and OPP management practices.

Decarbonisation Strategies for Palm Oil Value Chain

Various efforts have been implemented to decarbonise palm oil value chain. Such efforts can be generally categorised into two categories which are nature-based solutions (NBS) and engineered solutions. NBS aims to restore nature’s carbon sink, while engineered solutions are using technologies to capture carbon emission for storage and utilisation.

Nature-based solutions (NBS)

Based on the current practise, biomasses in the plantation (oil palm frond) and palm oil mill (EFBs) are transported and placed at the plantation for mulching purpose to return the nutrient back to the soil. To enhance the performance of the nutrient recovery from EFBs, EFBs can be converted into biofertilizer via fermentation process. Via such process, the produced biofertilizer has higher nutrient content and easier to be absorbed by the tree. Besides, it also reduces the time of degradation of such biomass in the field. Besides, PKS can be converted into biochar and return to the plantation as carbon storage which is considered as negative emission. At the same time, biochar also improve the microbial activity in the soil.

Engineered solutions

To capture carbon dioxide from the processing facilities (palm oil mill and refinery), the established carbon capture technologies (such as adsorption and absorption systems) can be deployed. The captured carbon dioxide can then be converted to valuable products such as biofuels, chemicals, or construction materials. However, due to the complexity of the technologies and economical consideration, such technologies are not considered in the palm oil sector. On the other hand, most of the stakeholders are focusing on recovering and converting palm-based biomass into value-added products as well as extraction of biogas from POME. Such efforts able to reduce the carbon and greenhouse gases emission from the degradation of biomass and treatment of POME.

Anaerobic digestion of POME via covered lagoon and tank systems are commonly used in the palm oil mill to convert organic materials in POME into biogas (~60% methane purity). Besides, wastewater in the refinery is also able to generate biogas via anaerobic digestion system. Such biogas can be upgraded to biomethane (> 92% methane purity) via purification technologies (e.g., membrane separation, adsorption technology, etc.). The generated biomethane can be used as transportation fuel and supply to the national gas pipeline.

In addition, other solid palm-based biomass (e.g., PKS and mesocarp fibre) are utilised as biomass fuels in combined heat and power (CHP) system to generate steams and electricity to fulfil the processing facilities’ demand. While EFBs can be converted into various products such as pellet, briquette, dried long fibre, etc. which then can be utilised in other industries as feedstock or energy sources. Dried long fibre is commonly used in mattress manufacturing. Meanwhile, briquette and pellet are commonly used as cofiring materials in power plant to reduce fossil fuel consumption, which contribute to indirect carbon emission reduction.

For the transportation and machinery used within the value chain, biodiesel can be used to replace the fossil fuel-based diesel. In addition, the transportation trucks can be modified to be powered by biomethane instead of diesel.

Note that abovementioned efforts can contribute to the decarbonization of palm oil value chain. However, based on the current industry practices and feedback of the stakeholders, limited technologies and strategies are deployed due to various constraints, such as poor economic performance, low efficiency and accessibility, requires high technical personnel, etc.

Role and Responsible of Chemical Engineers

Viewing the complexity of the value chain which involves multiple management practices, technologies and products, it is important to develop systematic strategies and action plans which able to be contextualised based on geographical, economic, environmental, political and cultural constraints. Chemical Engineers play a vital role in this decarbonization journey of palm oil sector.

- Develop and implement circular economy framework: Such framework aims for promoting material and energy recovery and exchange with multiple industries as well as expend the utilization of palm-based biomass in other industries.

- Enhance the energy efficiency and technology performance: Most of the processing facilities have been utilised for more than few decades, therefore, it is important to develop new technologies which able to enhance the oil extraction performance as well as reduction of energy consumptions.

- Renewable energy utilization: Integrating renewable energy sources in palm oil processing facilities and transportation, such as solar, biogas, biomethane, and biomass, can significantly reduce greenhouse gas emissions. Biogas generated from wastewater and POME through anaerobic digestion can replace fossil fuels, providing renewable energy for on-site operations and potentially even supplying excess energy to the grid.

- Sustainable transportation and logistics: Synthesizing a sustainable supply chain of supply chain by optimizing the selection of transportation mode, fuel type and transportation route. This can include utilizing more energy-efficient vehicles, adopting alternative fuels, optimizing routes to minimize distances traveled, and exploring low-carbon transportation options like rail or waterways.

- Deployment of carbon capture and utilization: Enhancing the performance of carbon capture and utilization (CCU) technologies which can offset the emissions generated during palm oil production. Novel utilization of carbon dioxide in chemical, food, manufacturing industries need to be further explored.

- Sustainable process and product design: By integrating advanced artificial intelligence into process and product design, it is able to generate novel systems and molecules based on different optimization objectives. Using the newly design framework, novel process configuration can be implemented in palm oil processing facilities. Besides, alternative sustainable products can be developed from palm oil industry to fulfil the growing global demand.

By integrating circular economy principles with decarbonization strategies, the palm oil industry can reduce its carbon footprint, contribute to climate change mitigation, and work towards a more sustainable and low-carbon future. Chemical Engineer serves as the main pillar in the decarbonization journey for palm oil sector. With the fundamental knowledge on process synthesis and design, as well as process integration and optimization, chemical engineer will be able to transform the industry and achieve net zero target.

Palm Oil Value Chain (Adapted from Tan et al., 2024)